Products

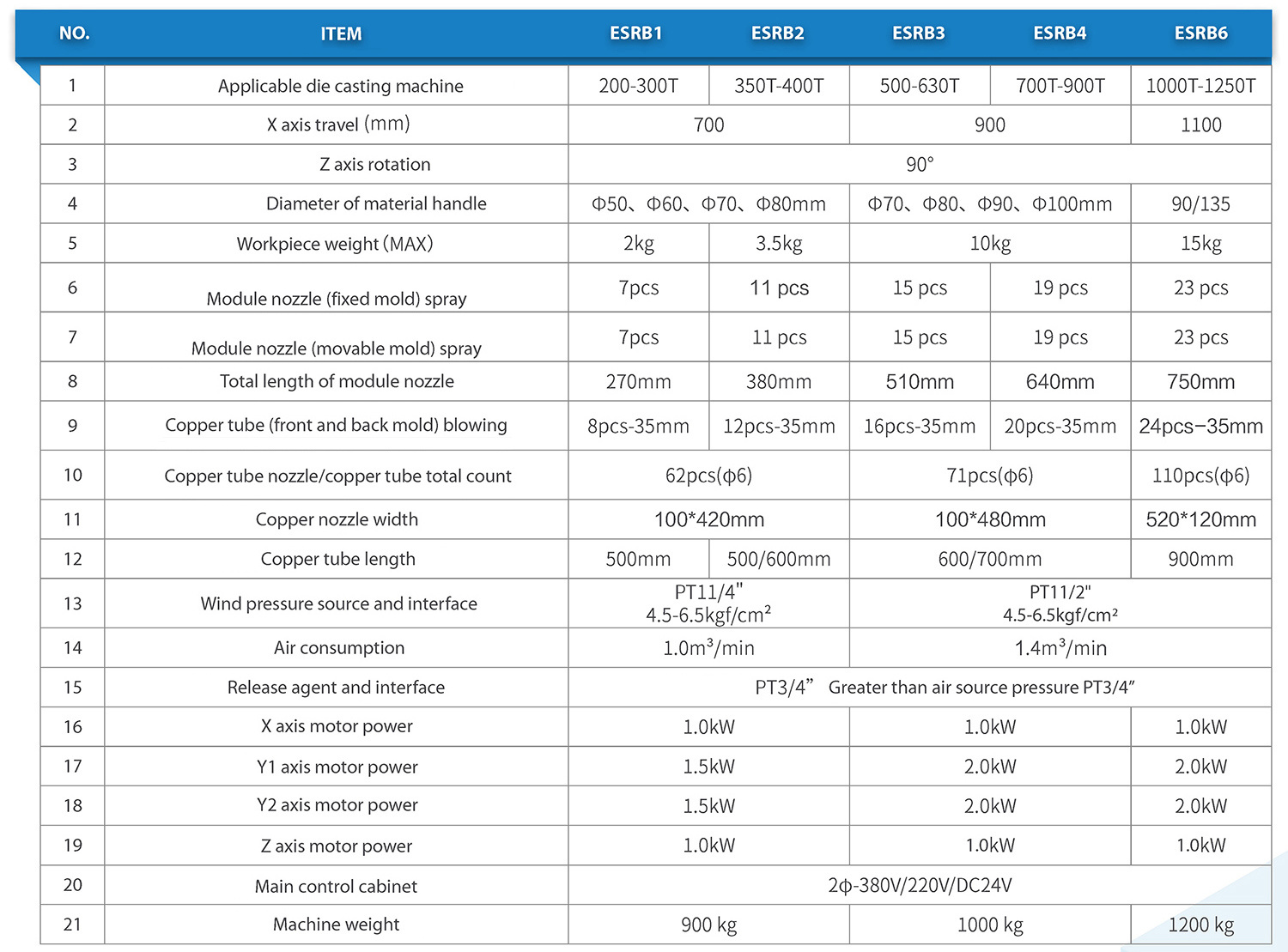

Spray and take integrated robot

Four-axis full-servo drive, which can be single-acting or connected with die-casting machine and soup feeder for fully automatic production.

keyword:

Spray and take integrated robot

Category:

Spray and take integrated machine

Hotline:

Spray and take integrated robot

1.Four-axis full-servo drive, which can be single-acting or connected with die-casting machine and soup feeder for fully automatic production.

2.Small size, simple structure, convenient operation, convenient maintenance and few failures. Customers are extremely advantageous for the configuration of die casting machines with limited removal positions.

3.The take-out mechanism selects the screw-in fixed-point take-out function, and the screw retreats the material discharge fixed-point function, which does not hinder the spray mechanism and facilitates the upper and lower molds.

4.When the take-out/spray mechanism works, it moves approximately linearly in the upper and lower positions of the cavity.

5.The take-out and spray mechanism adopts a linkage structure, and the take-out, spray and rotating mechanism adopt RV reducer with servo drive, which has high mechanical strength, good stability and long service life.

6.The spray mechanism can be equipped with copper tube nozzles or modular nozzles, and can be interchanged.

7.Modular nozzle atomization amount can be adjusted individually, spray control method: front left and right separate spray, front middle spray, rear left and right separate spray, rear middle spray; blowing control method: front and rear copper pipes blowing at the same time or spray mode changed to blowing mode. (Note: ESRB2# comes standard with front separate spray and rear separate spray. If you need front left and right separate spray, front middle spray, rear left and right separate spray, rear middle spray, please contact our company!)

Copper tube spray control method: any one spray or simultaneous spray before, middle and rear. Blow control method: any one blow or simultaneous blow before, middle and rear;

8.Spray Y2-axis arm at any point to do fixed-point spray, circulating spray, floating spray and air blowing.

9.This device adopts PLC and touch-sensitive human-machine interface (HMI) for action control and parameter setting, and can store multiple sets of mold removal/spray programs in the system according to the requirements, and directly call and store in the human-machine interface when changing molds The program can be used directly, making operation and maintenance convenient.

Pre

Next

Pre

Servo Extractor

Next

Guestbook

Address: No. 19 Chuangye South Road, Songxia Industrial Park, Shishan Town, Nanhai District, Foshan City, Guangdong Province

QQ:3221489420

Fax:0757-85432639

Wechat official account